Another measure is curtailing human resource expenses while ensuring higher productivity at the same compensation by reducing idle time or unproductive sessions. Simultaneously, the managers can reduce the indirect manufacturing overheads by saving on utilities. Calculating manufacturing costs helps determine pricing, control expenses, and maximize profits. Use the total manufacturing cost formula to accurately track production costs and optimize efficiency. Direct Materials are the raw materials used in the production of goods. This includes all materials that can be traced directly to https://www.bookstime.com/ the finished product.

- Direct Labor refers to the wages paid to workers who are directly involved in manufacturing the product.

- This data is helpful in setting the lowest purchase price that will guarantee a profit after recovering such items as advertising, distributing, and administration expenses.

- It also ensures that products are priced competitively while still allowing for a healthy profit margin.

- Or you may research some other potential partners, who can provide you with a better price (whilst supplying you with equally good materials).

- Rather, total manufacturing costs include all related costs accrued in the period.

- Knowing your manufacturing costs is fundamental when working towards profitability.

Inventory Labeling Guide for Small and Growing Businesses

It does not include the general management team and others who are not directly involved in the assembly line. Direct materials refers to raw materials and any additional parts that were used to create the final product. Any material that can be directly assigned to a specific product line is considered a direct material. An example of a direct material is rubber used to make a tire or fabric total manufacturing cost formula used to make a dress. Knowing your manufacturing costs is fundamental when working towards profitability.

The Importance of Understanding Manufacturing Costs

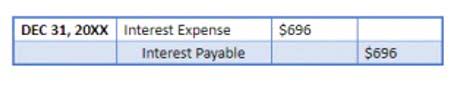

Essentially, it represents the total cost of producing the goods that will be sold to customers. Timesheets can help manufacturers streamline their payroll with a secure process that includes locking timesheets once submitted to managers, who can review and route them to payroll. But they also serve as a means of monitoring labor costs to make sure you’re not overspending your budget. Managers can view timesheets to monitor labor costs and get further information by generating a timesheet report.

How to use the total manufacturing cost formula to decrease costs?

- We are aware of few businesses, that tracks a small thread and amount of adhesive that are used in the assembly of Machines components.

- Cost control, according to Fabrizi, is one of the top benefits of calculating manufacturing costs.

- When companies regularly track the total manufacturing cost, they get a better idea of areas to save expenses and eliminate wasteful spending.

- Like TMC, COGM considers a company’s total expenses while producing a finished product.

- The first step for calculating total manufacturing cost is gathering cost data.

Learn how to compare manufacturing costs quickly and accurately with aPirori’s digital factories. To find the detailed breakdown of manufacturing overhead, you would need to refer to your company’s internal cost accounting records. Manufacturers can compare the costs of making a product using different manufacturing processes. This helps them understand the most efficient process and the investment they need to make for the selected process. With a breakup of all the costs of manufacturing, management can decide whether it is more profitable to purchase certain parts or materials from a vendor or manufacture them in-house.

- ProjectManager is award-winning project management software that tracks manufacturing costs in real time.

- Calculate manufacturing overhead costs by summing up your facility’s indirect expenses.

- Each of these costs is usually listed as separate line items on an income statement, which is the financial results of the business for a stated period.

- The consulting firm was also able to re-negotiate the manufacturing company’s contracts with poor-performing suppliers.

- While we have many project views, the Gantt chart contains key details on how much you’re spending on production.

- This data is critical to make informed decisions about where to locate production facilities, source materials, and allocate resources.

Understand & Manage Your Manufacturing Costs with Confidence

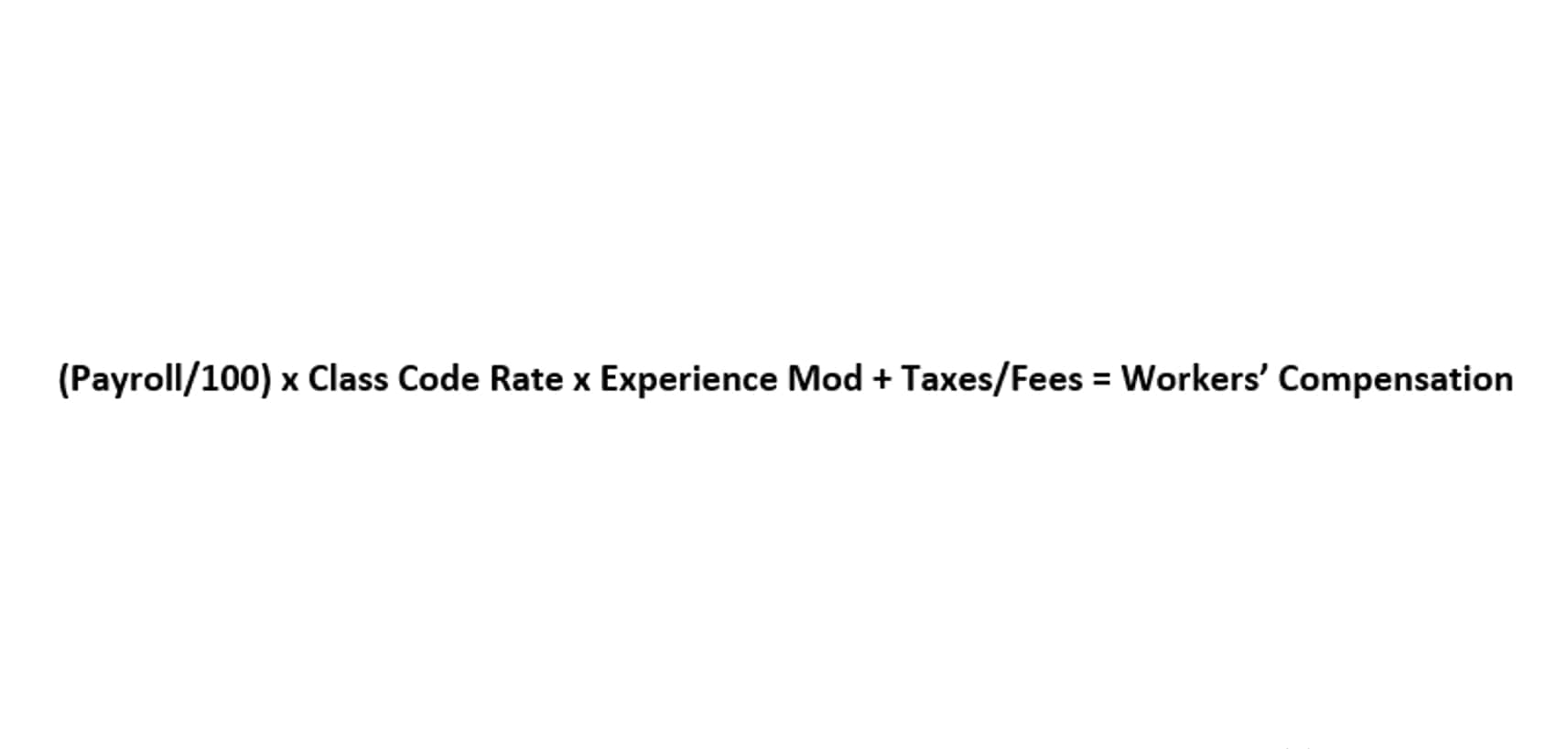

Indirect manufacturing costs include all other expenses incurred in manufacturing a product except direct expenses. Besides cost control and financial planning, TMC also helps Payroll Taxes companies with inventory valuation. It helps calculate the cost of goods manufactured (COGM) and, subsequently, the cost of goods sold (COGS).